Feasibility of industrial high-temperature heat pumps up to 250°C

Possible cycle designs and the matter of the appropriate refrigerant

In recent years, developments in the field of industrial heat pumps have focused on two main aspects. On the one hand, there has been an increase in the establishment of heat pumps with relevant thermal capacities for industrial processes. On the other hand, the development went towards higher utilization temperatures to over 100°C. Increasing operating temperatures of heat pumps make it possible to supply heat to industrial processes that were previously not possible with heat pumps. Therefore, higher utilization temperatures lead to new types of applications for high-temperature heat pumps [1,2]. Both established manufacturers and start-ups are developing products and components that can be deployed in this market.

At present, the often-perceived utilization temperature limit is approximately 150°C. Reciprocating and screw compressors are predominantly used, with corresponding requirements for the lubrication of the compressors. [2-5]. If one pursues the idea of increasing the operating temperatures in order to be able to supply additional industrial processes in the future, and if one wants to find out where the economic and technological boundaries will be, it is necessary to deal with the requirements on the lubrication. Although utilization temperatures of up to 180°C seem technically feasible with reciprocating and screw compressors, beyond that, other technologies with lubricant-free compression may be advantageous.

This approach is being investigated by the project partners Vienna University of Technology - Institute of Energy Technology and Thermodynamics and AIT Austrian Institute of Technology - Center for Energy. The techno-economic feasibility of centrifugal compressors in high-temperature heat pumps with appropriate refrigerants and adapted cycle designs for a heating capacity of about 1 MWth is being investigated. In this paper, a refrigerant preselection and a description of possible cycle designs are given. Based on this, parameters and results of a comparative calculation are described.

Refrigerant preselection and cycle design

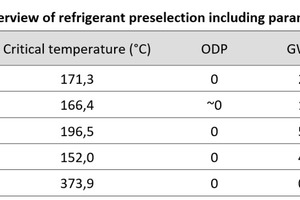

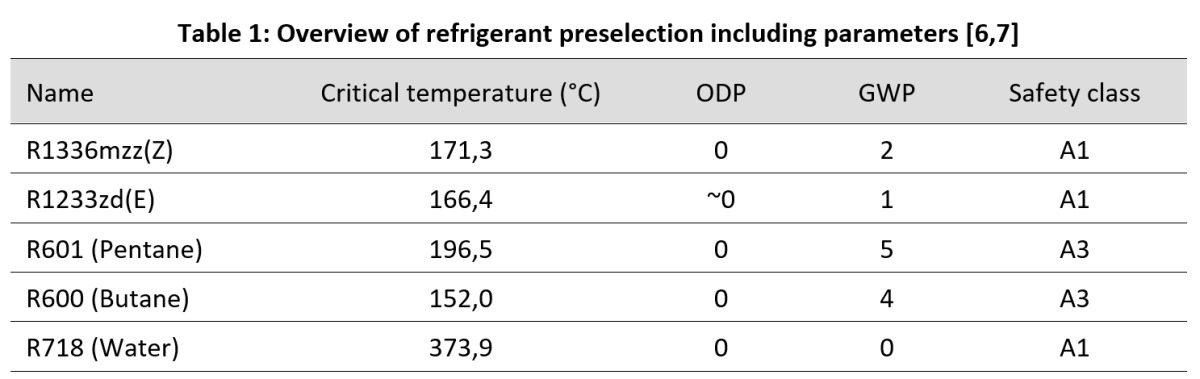

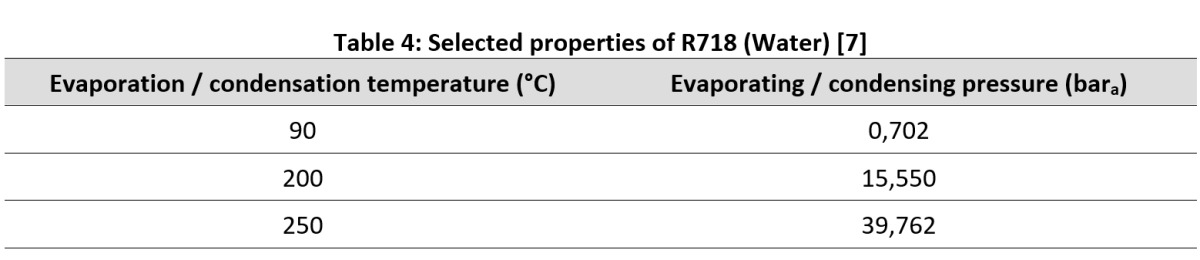

In general, the authors are aware that refrigerants have direct and indirect effects on the environment. The pre-selection presented here includes natural and synthetic refrigerants and is based on physical and thermodynamic parameters. Essentially, the critical temperature, the ODP value, the GWP value and the safety class are used (see Table 1). This is already simplified since, for example, the volumetric heating capacity must also be considered. However, this is done indirectly through the following comparative calculation. Water (R718) stands out in the preselection because it is the refrigerant with the highest critical temperature. All, except water, result in transcritical operation at a heat sink outlet temperature of about 200°C.

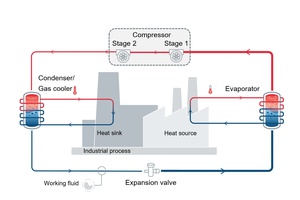

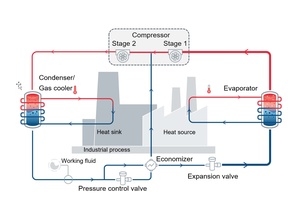

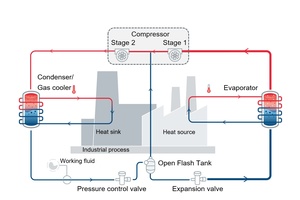

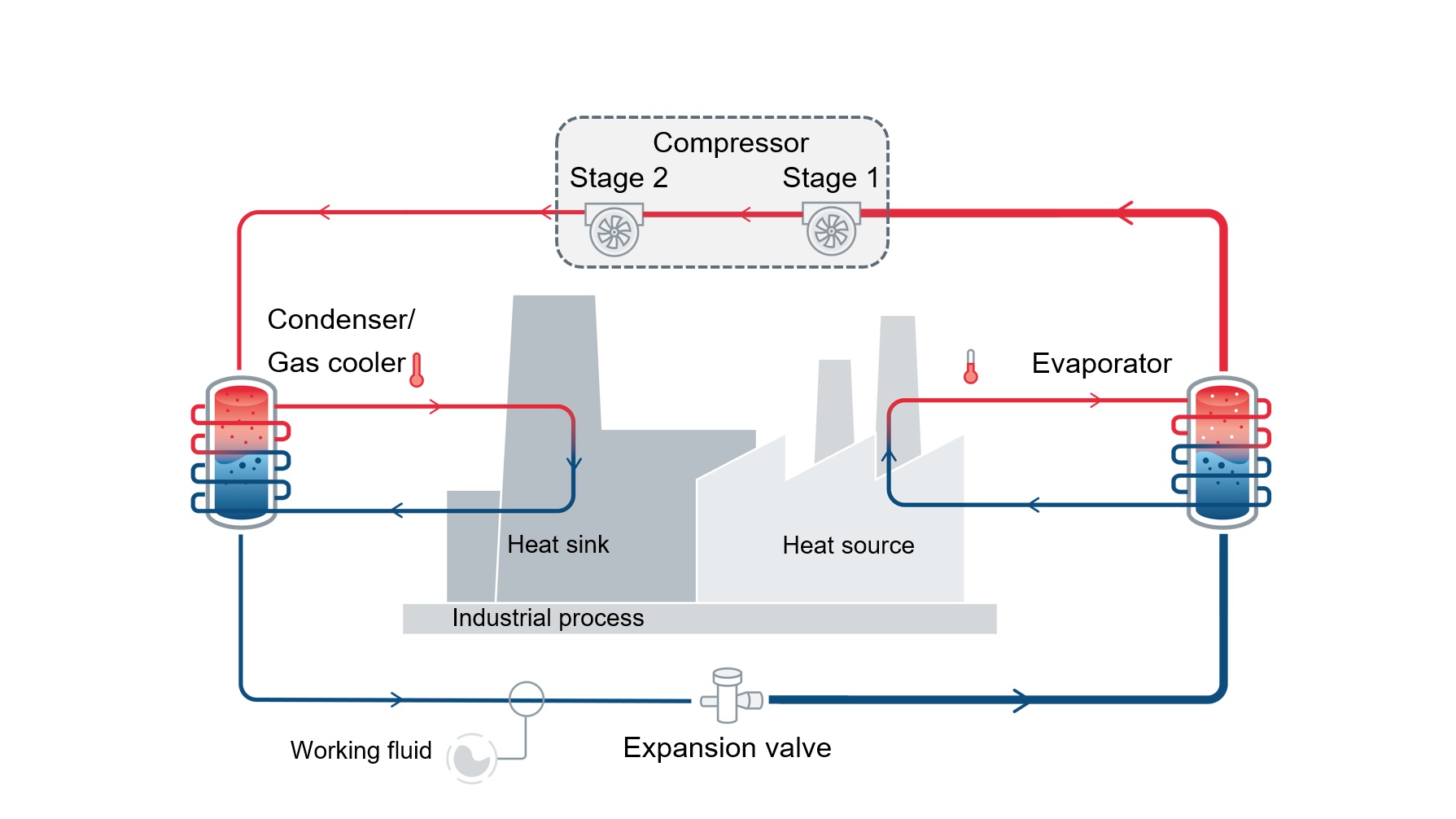

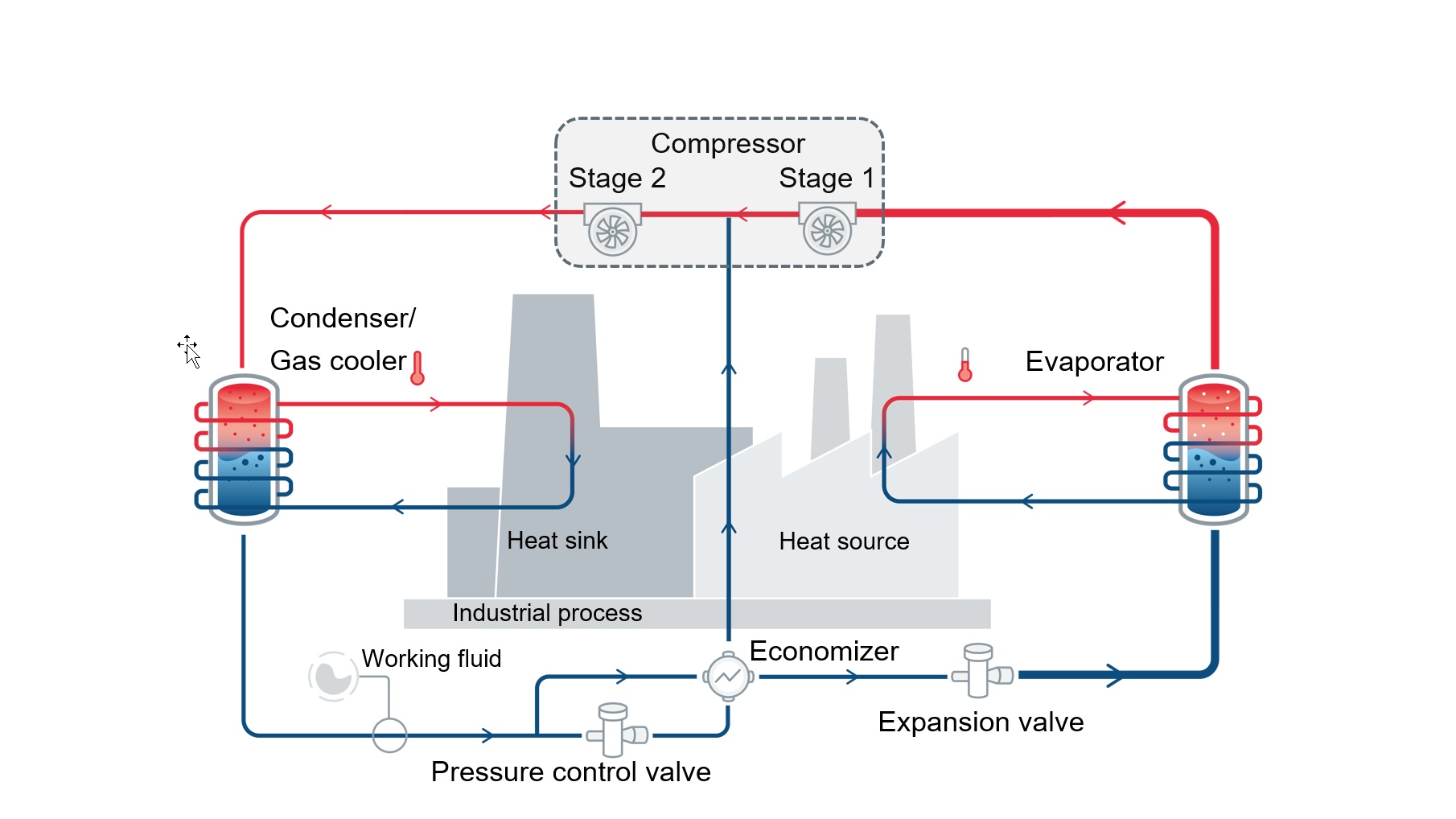

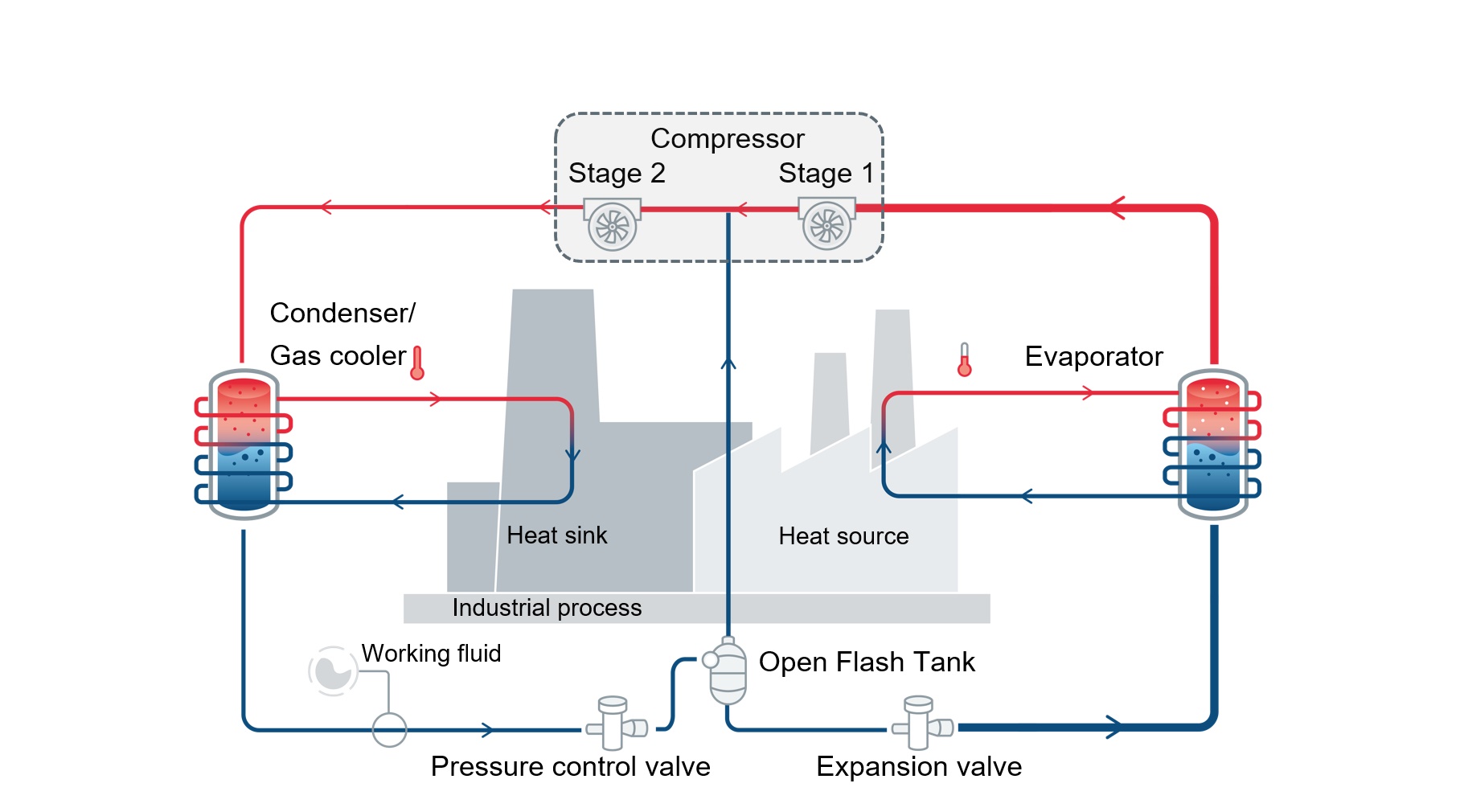

The potentially suitable cycle designs focus on limited complexity and thus on two-stage compression with centrifugal compressors. The respective pressure ratio of the individual compression stages is thereby reduced and leads to higher compression efficiency with centrifugal compressors. The reference cycle design is shown in Figure 1. Two-stage compression opens up the possibility of intermediate injection. This can be done from an economizer (Figure 2) or an open flash tank (Figure 3). The illustrations are simplified as the comparative calculations include an internal suction gas superheater which transfers heat from the gas cooler/condenser outlet to the suction side of the first compressor stage.

Figure 1: Basic scheme of the "Reference" cycle design

Figure 1: Basic scheme of the "Reference" cycle design

Bild: AIT

Figure 2: Basic scheme of the "Economizer" cycle design

Figure 2: Basic scheme of the "Economizer" cycle design

Bild: AIT

Figure 3: Basic scheme of the "Open Flash Tank" cycle design

Figure 3: Basic scheme of the "Open Flash Tank" cycle design

Bild: AIT

Comparative calculations of the concepts

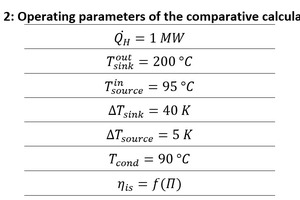

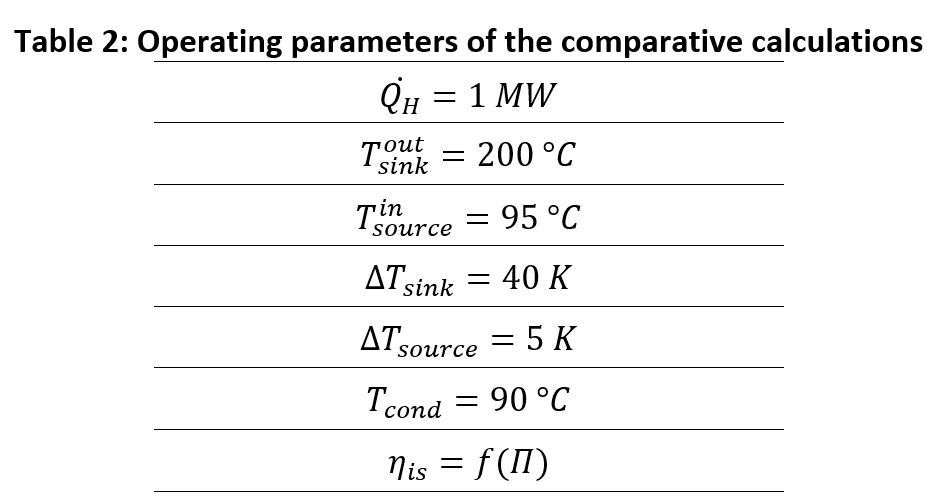

The comparative calculations carried out are intended to give a first impression of what operating results can be expected. For the comparative calculations described here, the three cycle design models were implemented in "Dymola/Modelica" and operation with four different refrigerants was simulated. The selected operating parameters are listed in Table 2. In order to establish comparability between the different refrigeration cycle designs, an equal hot gas temperature was modelled.

For the refrigerants R1336mzz(Z), R1233zd(E) and R600 (butane), there is basically a transcritical operation. With R601 (pentane), the operating mode is close to the critical point, which is assessed as transcritical to simplify matters.

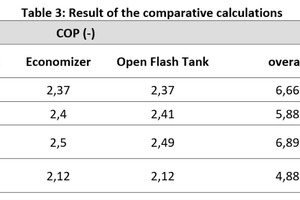

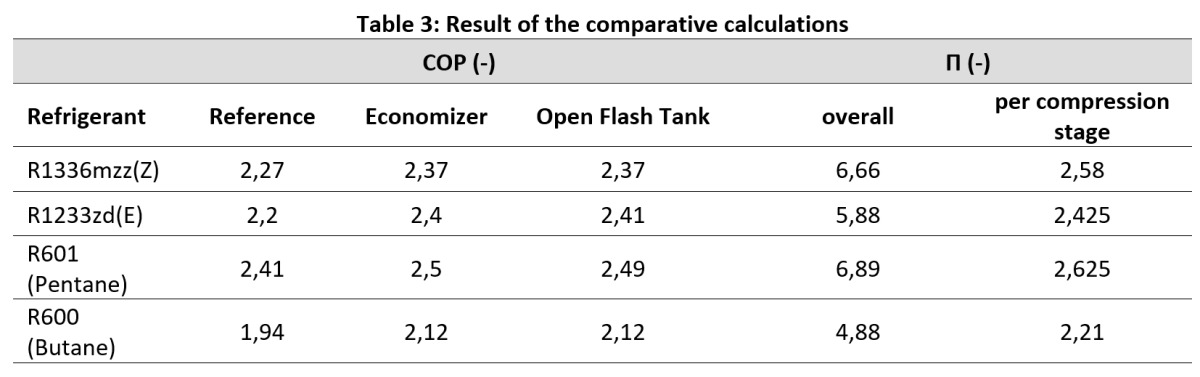

Table 3 shows the results of the comparative calculations using the COP according to Equation (1) - and the pressure ratios Π according to Equation (2). The COP is approximately between 2 and 2.5, which corresponds to the expected value at a temperature difference of about 110°C.

The results (Table 3) for the refrigeration cycle designs "economizer" and "open flash tank" differ only insignificantly. This means that the system with fewer or less expensive components and a simpler control system is clearly preferable. However, if the COP is considered in comparison to the reference cycle, a noticeable gain in efficiency can be seen in both cases.

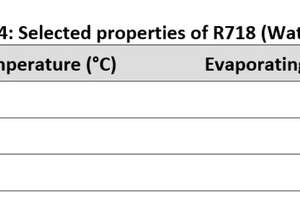

Water is considered separately here because it differs significantly from the other refrigerants due to its thermodynamic properties, such as the very high critical temperature (Table 1). This clearly results in a subcritical mode of operation for the operating conditions mentioned. Considering in a simplified way the pressures of water during condensation and evaporation , this results in the values shown in Table 4.

If we calculate the pressure ratio Π for compression from 90°C to 200°C according to Equation (2), we get ΠTotal = 22.15, which corresponds to a value of 4.71 per stage with two compression stages. If the sink temperature is now increased to 250°C, the result is ΠTotal = 56.64, which can again be divided into two stages with 7.5 each.

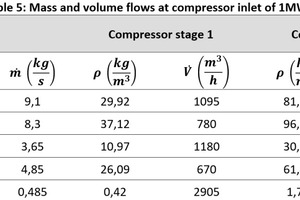

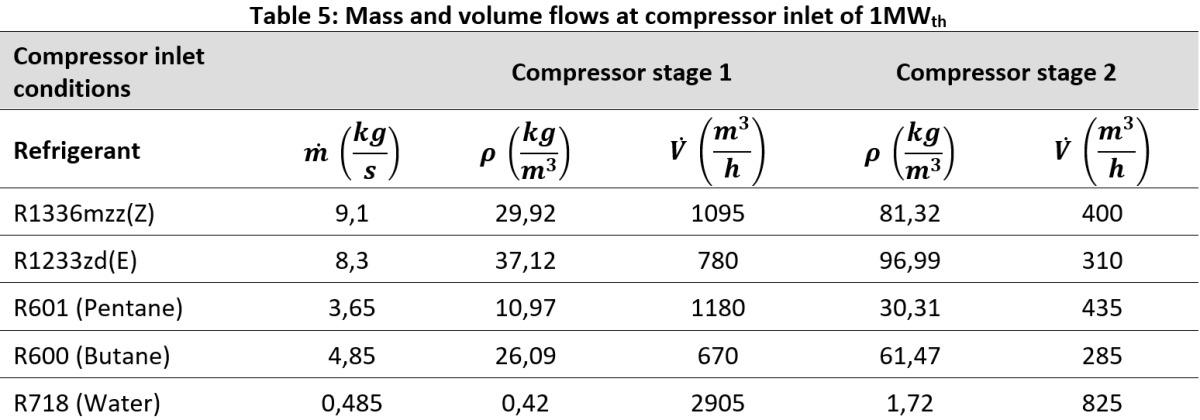

Another important aspect of the use of water is the low density in the gaseous state at these temperatures compared to other refrigerants, and the resulting low volumetric heating capacity. To illustrate this, the suction-side volume flows of the compressors were calculated and compared in Table 5. It can be seen that the volume flow of water at the same source and sink temperatures is about two to four times greater than that of the other refrigerants. For the construction of a system, this results in increased costs, which cannot be quantified in more detail at this stage of the investigation.

Summary and conclusion

The evaluations and comparative calculations described in the previous sections show that using oil-free centrifugal compressors in two-stage cycle designs would enable high operating temperatures at high temperature lifts. Calculated pressure ratios for cycle designs with R1336mzz(Z), R1233zd(E), R601 (pentane) and R600 (butane) are in the feasible range but lead to transcritical operation of the cycles.

Due to its properties, the use of R718 (water) does not appear to be practical when limited to two compression stages. In addition, the volumetric heating capacity of water at the targeted operating conditions is significantly lower compared to the other refrigerants, which is why the required volumetric flow rate when using R718 (water) would be two to four times higher. The expected COPs for the cycle designs with R1336mzz(Z), R1233zd(E), R601 (pentane) and R600 (butane) appear promising. However, the comparative calculations not only serve to estimate the COPs, but in particular the specific operating conditions of the compressors can be derived from them for further work. The suction gas superheater plays a special role. For the sake of simplicity, it was not drawn into the cycle designs, but it transfers heat from the gas cooler/condenser outlet to the suction side of the first compressor stage. Thus, it determines the inlet temperature of the refrigerant at the suction connection of the first compressor stage, which has a significant influence on the compressor outlet temperature of the second stage and therefore on the achievable utilization temperature.

For a complete techno-economic assessment, many more aspects need to be considered in addition to the results described in this article, and potential problems need to be both identified and addressed. These include refrigerant-specific, engineering, propulsion, and control issues. It should also be mentioned that unused waste heat at a temperature level of about 90°C is not easy to find. Therefore, it also seems necessary to carry out further process analyses in order to be able to estimate the market potential.

Hier gelangen Sie zu diesem Artikel in deutscher Sprache.

Bild: Klima- und Energiefonds / Österreichische Forschungsförderungsgesellschaft

Bild: Klima- und Energiefonds / Österreichische Forschungsförderungsgesellschaft

References

[1] C. Arpagaus, F. Bless, M. Uhlmann, J. Schiffmann, S.S. Bertsch, High temperature heat pumps: Market overview, state of the art, research status, refrigerants, and application potentials, Energy 152 (2018) 985–1010.

[2] F. DI(FH) Helminger, Steam generating heat pumps: Upcoming technology for heat recovery, Nuremberg, 2021.

[3] D. Schlehuber M.Sc., CHALLENGES IN THE DEVELOPMENT OF POSITIVE DISPLACEMENT COMPRESSORS FOR HIGH TEMPERATURE HEAT PUMPS, Nürnberg, 2021.

[4] Heaten AS, 1MW HeatBooster: Key product characteristics, https://www.heaten.com/, accessed 5 November 2021.

[5] SPH Sustainable Process Heat, The heat pump: Product description, https://www.spheat.de/?lang=en, accessed 23 May 2022.

[6] C. Arpagaus (Ed.), Hochtemperatur-Wärmepumpen: Marktübersicht, Stand der Technik und Anwendungspotenziale, 1st ed., VDE Verlag, 2018.

[7] NIST, Reference Fluid Thermodynamic and Transport Properties Database (REFPROP): Version 10, https://www.nist.gov/srd/refprop, accessed 5 January 2021.